Client

Project

Location

About the project

Design

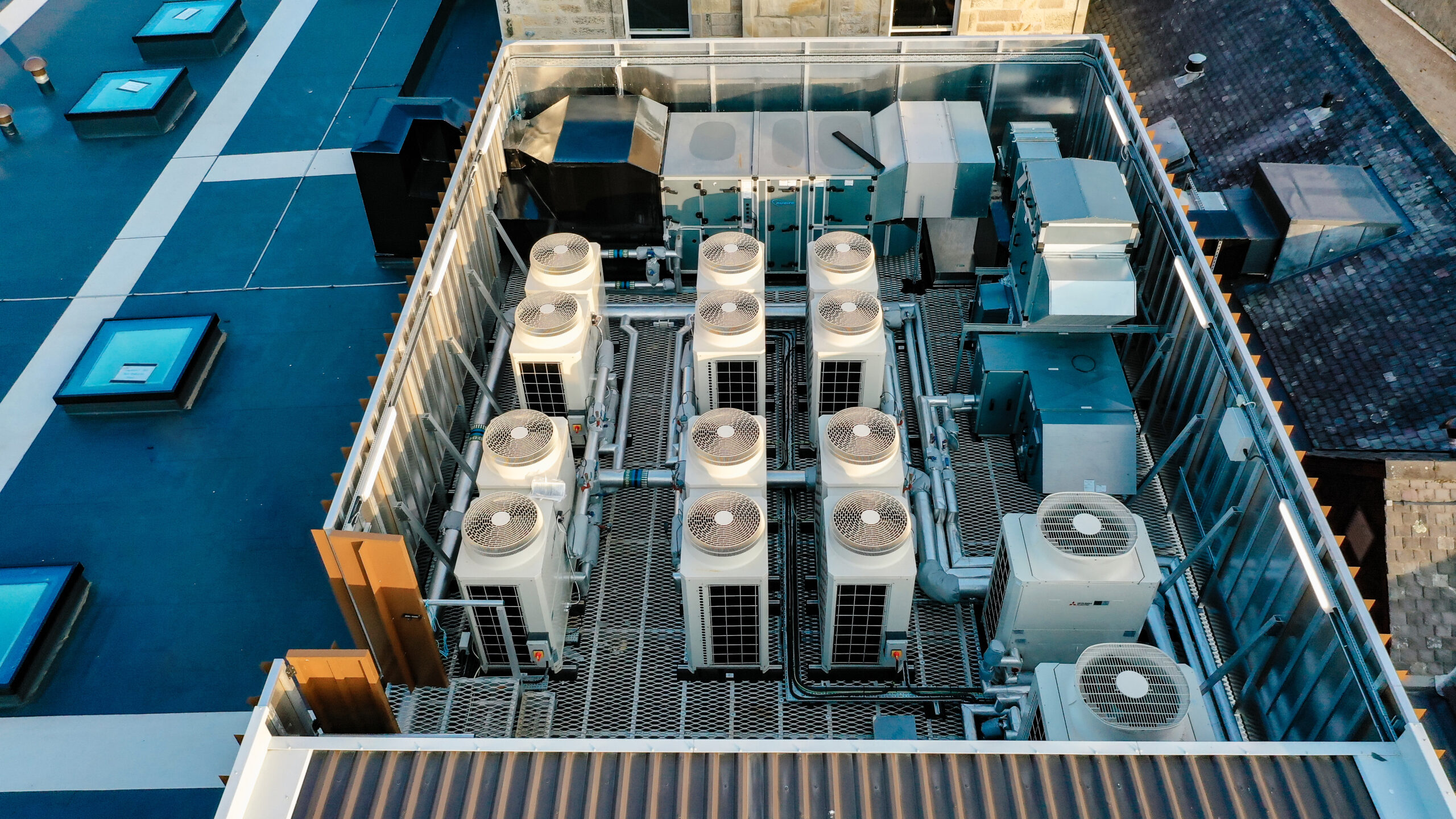

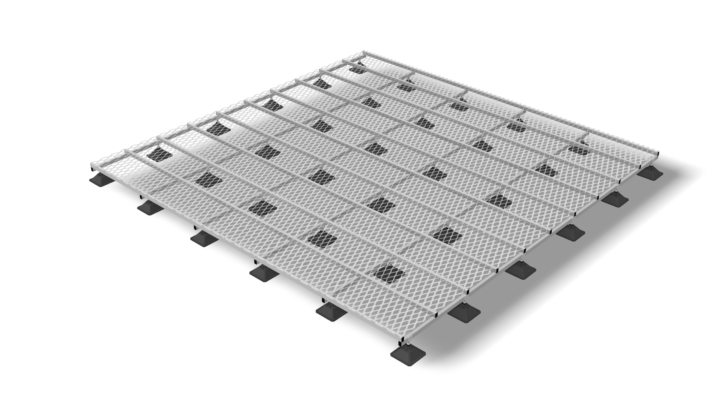

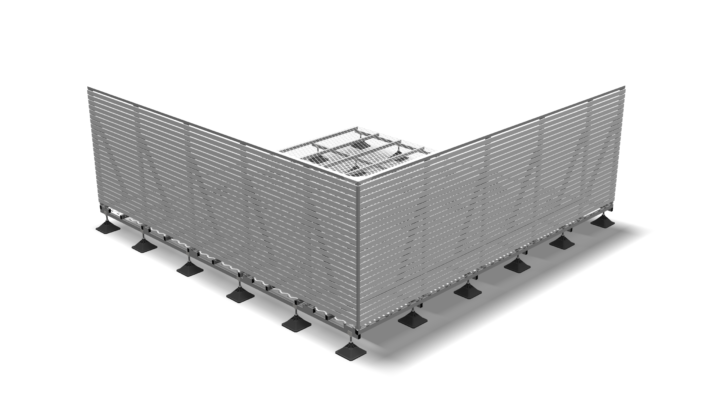

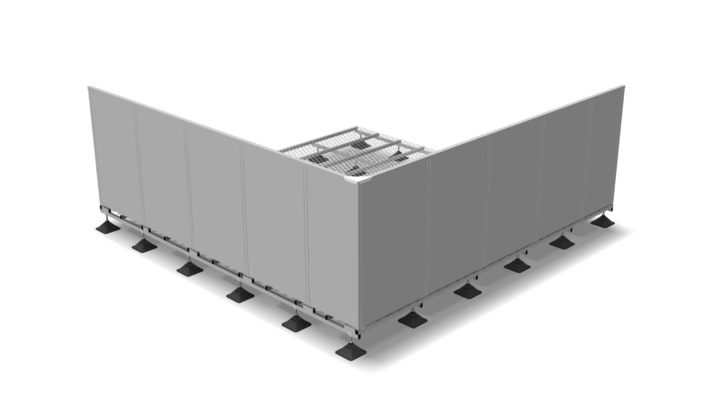

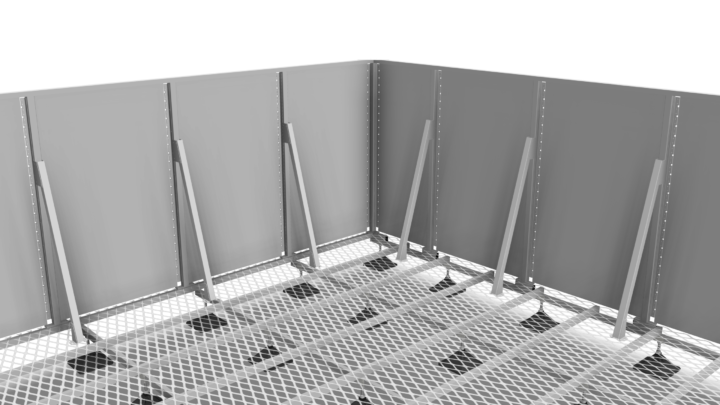

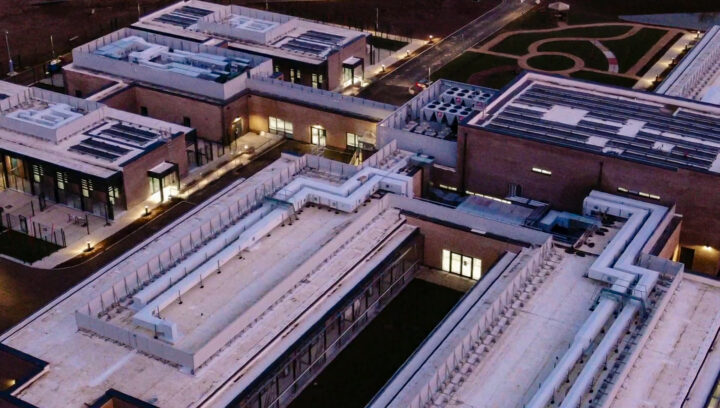

To address the site’s demanding wind conditions, we used our Series 2 platform system as the structural base for mounting the air source heat pumps. This was integrated with our Speedscreen ballast weighted screen system, allowing the combined mass of the ASHPs and platform to be used as ballast — an efficient method of wind loading mitigation that eliminated the need for roof fixings. The screen itself was constructed using our Louvre100 panels, powder-coated to a bespoke colour to suit the project’s architectural palette. As with all our systems, the design was based on site-specific wind calculations, considering factors such as the location, roof height, surrounding terrain, and screen dimensions.

Key features

– Series 3 platform for a secure, non-penetrating deck to suit the roof design.

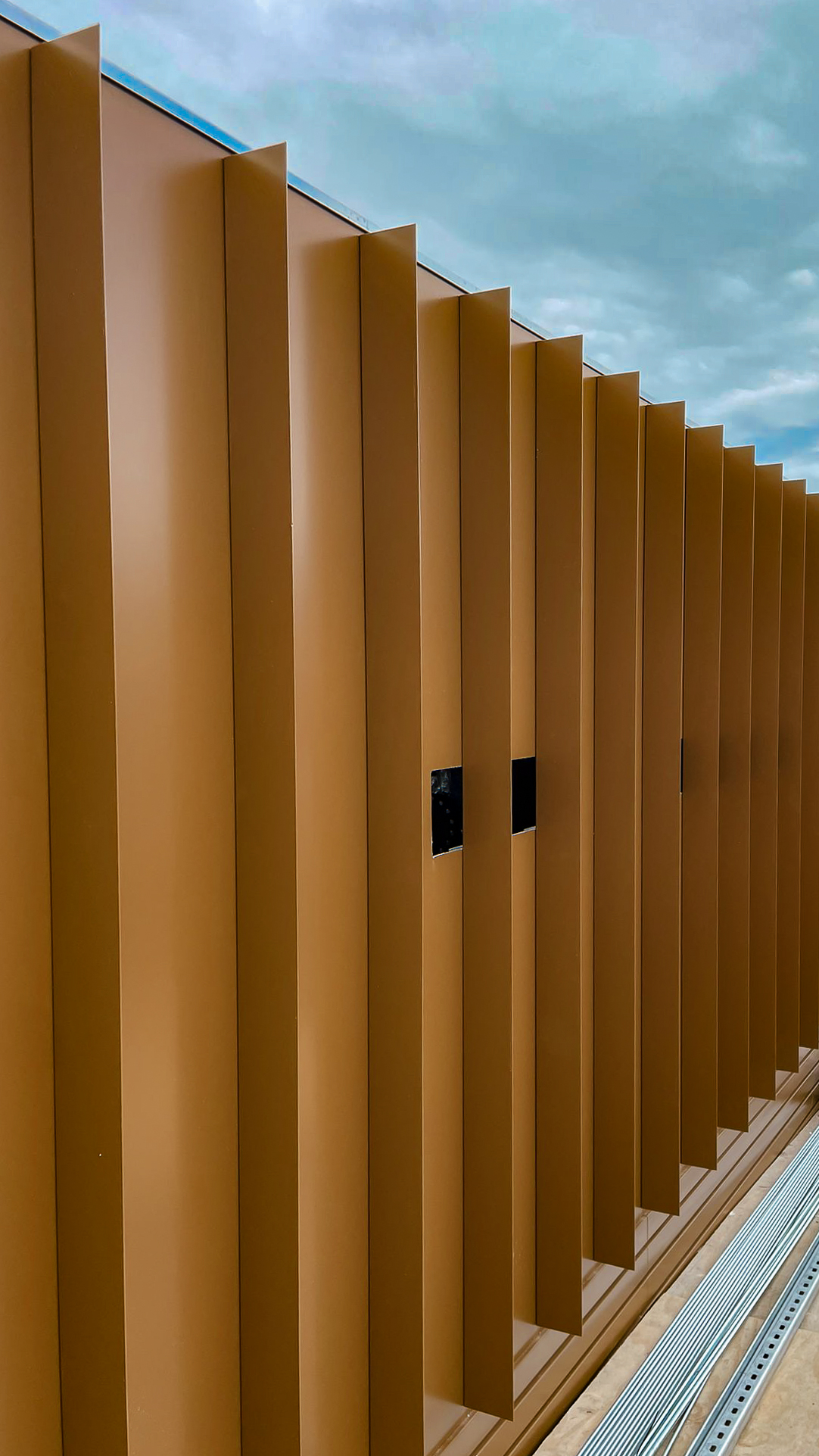

– FinScreen finish polyester powder-coated to align with the planning and architectural packages.

– Soundshield acoustic sheets creating a solid reflective barrier achieving a Rw of 28dB.

– Conforms to BS EN 516 2006 and BS EN 1090-3 2008

Installation

The complete enclosure was installed in just five days, with the modular, prefabricated design enabling a fast and efficient installation process. All parts were pre-fabricated in our factory in Leeds and delivered flat-packed to site in kit form, minimizing onsite waste and labour.

Configured Platforms is driven by its passion for reinventing Value Engineering concepts that are bold enough to break with tradition and bring to your project lighter, faster, smarter, surface mounted aluminium Platforms and leading edge acoustic solutions.