Client

Project

Location

About the project

Design

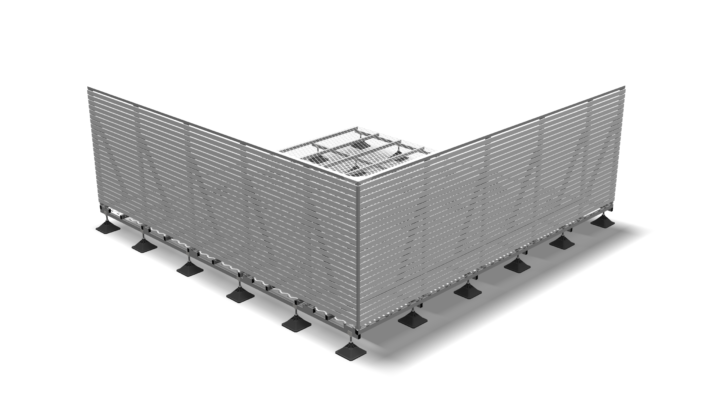

This solution maximized the use of limited space by incorporating a mezzanine level accessed via a hand railed step ladder. Our I-Bearer beam was utilized to provide a clear-spanning structural element, ensuring both strength and efficiency. The standard screens were continuous on the outside making a very tidy finish and screening off the equipment on both levels.

Key features

– Series 3 platform providing a secure, non penetrating deck to support the units

– Standard Screen PPC slats to visually conceal plant equipment

– Mezzanine level to maximise spatial efficiency

– Conforms to BS EN 516 2006 and BS EN 1090-3 2008

Installation

The entire installation was completed in just three days by a team of five installers, thanks largely to the modular design of the system. The prefabricated components were manufactured offsite in our factory in Leeds and delivered ready for rapid assembly, significantly reducing onsite construction time and labour requirements. This modular approach not only streamlined the installation process but also minimised disruption to ongoing site operations. The result is a fully functional, acoustically treated rooftop solution that delivers on structural integrity, operational efficiency, and environmental performance, all within a remarkably short project timeline.

Configured Platforms is driven by its passion for reinventing Value Engineering concepts that are bold enough to break with tradition and bring to your project lighter, faster, smarter, surface mounted aluminium Platforms and leading edge acoustic solutions.