Client

Project

Location

About the project

Design

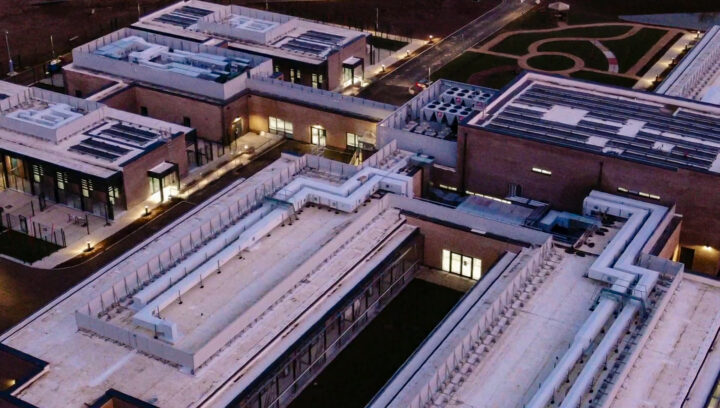

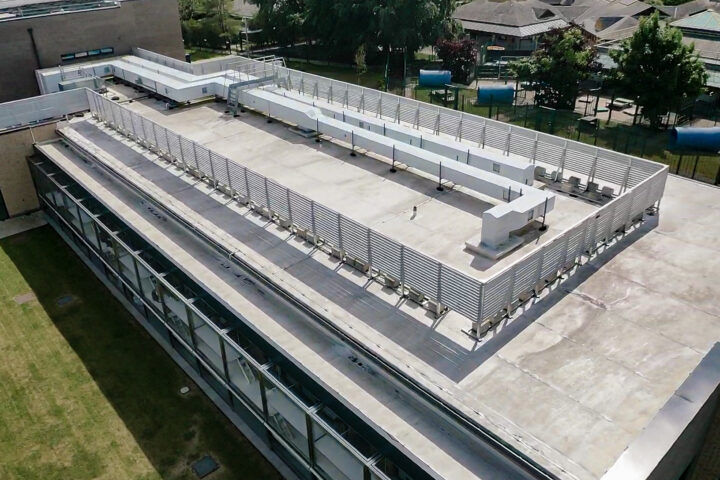

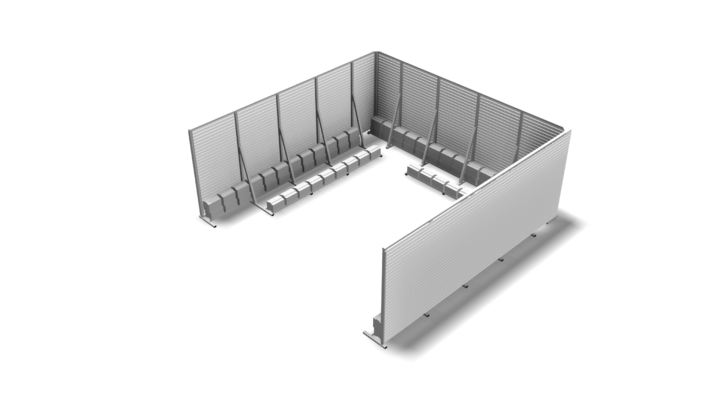

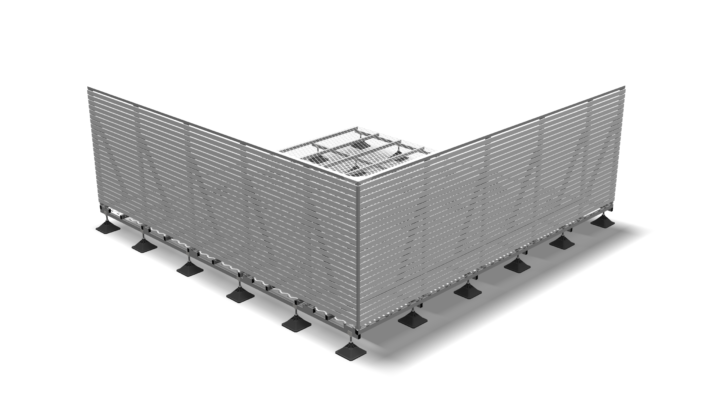

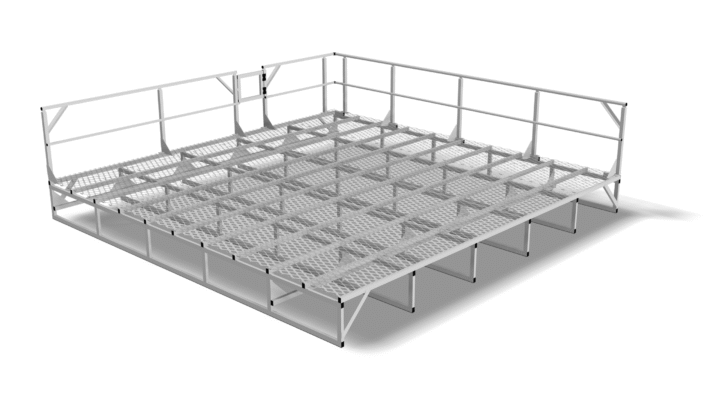

This low Speedscreen system was purposefully designed to hide unsightly air conditioning units and ductwork, ensuring a cleaner and more cohesive rooftop aesthetic. Spanning a whopping 453 metres all together, the screens not only delivered on visual impact but also on practicality. It was powder-coated to perfectly match the building’s exterior, helping it blend seamlessly with the overall architectural palette. Additionally, a Series 3 platform was used to mount specific HVAC equipment. The platform featured a specialised 6mm cushioning tape applied to its base, creating a soft interface between the structure and the roof surface. This approach ensured that rooftop equipment could be securely supported without compromising the membrane, required no penetrations and reduced vibration.

Key features

– Series 3 platform for a secure, non-penetrating rooftop solution.

– Ballast-weighted Speedscreen for enclosing and protecting equipment without any roof penetrations.

– Guardrail system and access steps to ensure safety for maintenance teams

– Conforms to BS EN 516 2006 and BS EN 1090-3 2008

Installation

The installation was successfully completed over a three week period by a dedicated five person team. Thanks to the modular, prefabricated design and the inclusion of clear, easy to follow instructions, the process was highly efficient from start to finish. The pre-engineered components arrived onsite organized and ready for assembly, significantly reducing installation time and complexity. The modular concept played a key role in the project’s success; ensuring there were no missing parts, no product waste, and no delays. This streamlined approach not only minimized onsite disruption but also enabled the team to complete the build smoothly and within the projected timeline.

Configured Platforms is driven by its passion for reinventing Value Engineering concepts that are bold enough to break with tradition and bring to your project lighter, faster, smarter, surface mounted aluminium Platforms and leading edge acoustic solutions.